Please read here more about seakeeping trials and numerical simulations of ships and structures in seaways.

Author: pa

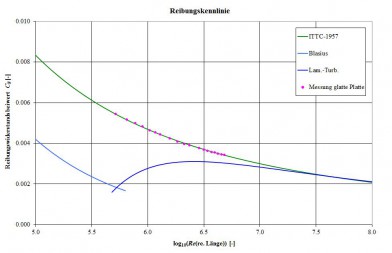

Frictional Resistance Measurement

The frictional resistance of a ship is a substantial part of the total resistance. This is influenced, among other things, by the texture of the skin (e.g., type of coating, degree of fouling). To minimise the power consumption and thereby reduce costs and protect the environment, it is therefore sensible to hold frictional resistance as low as possible by special coatings or surface structures. Corresponding studies can be performed on the friction measuring system. A roughness analysis of the surface by itself is not sufficient to deduce the exact frictional resistance. Experimental studies allow for more accurate conclusions. For this purpose, two plates with the coating to be tested are installed so that these form a narrow rectangular channel which is traversed by water in the friction test section. By the simultaneous measurement of the flow rate and the pressure loss along the test section and the water temperature, the wall shear stress can be detected and finally the frictional resistance coefficient of the plates is calculated. The results are transferrable to the frictional resistance of the ship. In order to cover the largest possible range of speeds, up to 20 m/s can be run in the friction measuring system.

These studies are not limited to the shipbuilding industry, but are also applicable in the aerospace and automotive industries. The results from the friction measuring system are also transferrable for these applications and can be profitably implemented where friction plays a role.

Context Related References / Research Projects

[1] Schulze, R.: Measurement of Skin Friction Drag and Design of Riblet Structures for a Ship Application, AIRBUS, Bremen, 30. Juni 2015

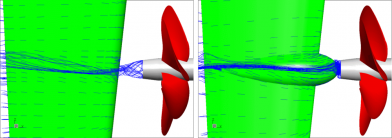

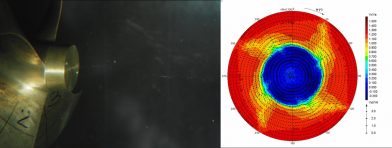

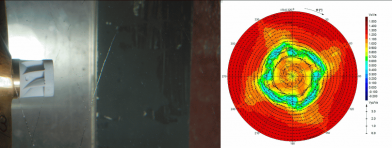

Potsdam Propeller Test Case PPTC

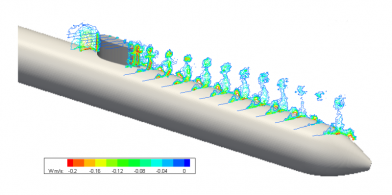

The Potsdam Propeller Test Case (PPTC) is a program for the validation of calculation methods for propellers. The PPTC propeller has been specially designed to enable researchers to validate calculation methods for propeller cavitation. The SVA design VP1304 (PPTC-Propeller) has, beside good hydrodynamic qualities, pronounced tip vortices, suction side and pressure side cavitation, root and bubble cavitation, and therefore is well suited for validation purposes.The open water characteristics of the propeller were measured at 0 ° and 12 ° shaft inclination. In selected points of operation the cavitation was recorded on the propeller optically. Additionally, extensive velocity measurements in the area of the blade tip as well as pressure fluctuation measurements were carried out. Within the framework of the International Symposium on Marine Propulsion in 2011 and 2015 respectively, a workshop has been organised on cavitation and propeller performance. In these workshops, the results of calculations from different tools were presented, analysed, and discussed and also compared with the experimental results.

For both workshops, the geometries, measurements, evaluations, reports and presentations are available on the website of the SVA (smp’11 and smp’15). The Proceedings of smp’11 and smp’15 also include presentations of the 1st and 2nd Workshop on Cavitation and Propeller Performance (www.marinepropulsors.com). The PPTC is also used by the ITTC as a benchmark for propeller calculations.

PPTC leads to various published data on the Potsdam Propeller Test Case and related projects.

Context Related References / Research Projects

[1] smp’11: 2nd Symposium on Marine Propulsors & 1st Workshop on Cavitation and Propeller Performance, June 17 -18, 2011, Hamburg, Germany

[2] smp’15: 4th Symposium on Marine Propulsors & 2nd Workshop on Cavitation and Propeller Performance, May 31 – June 4, 2015, Austin, Texas, USA

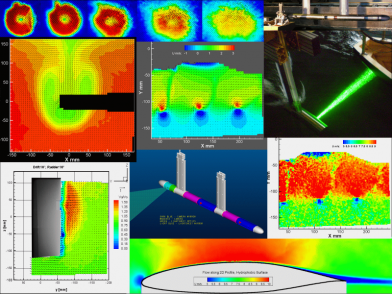

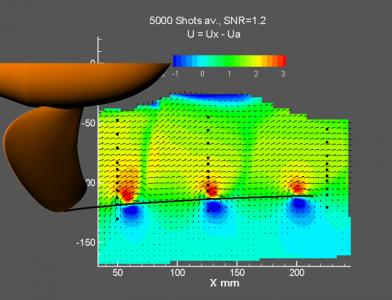

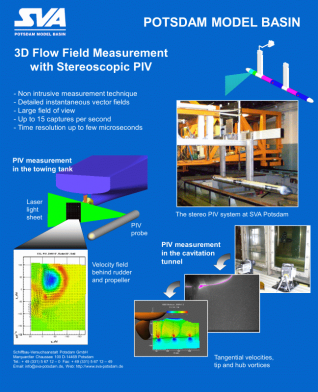

PIV – Particle Image Velocimetry

The process is very versatile. So far the following measuring tasks, among others, have been undertaken:

- Flow fields in the wake of ship models with and without working propellers

- Rudder dynamics with gap flow

- Decay of vortices on a generic wing

- Vortex flow around bilge keels

- Propeller wash of a thruster on a semi-submersible platform

- Propeller wash in the cavitation tunnel

- Flow around and wake of a submarine model with tower

- Flow around profile sections in the cavitation tunnel

With PIV the whole velocity field is measured in every frame. From the individual recordings the transient evolution of the flow can be visualized and also a mean velocity field can be determined by averaging all recordings. The desired spatial resolution determines the size of the field of view and the achievable number of vectors in the measuring range. The largest achieved measuring range so far had an extension of approximately 400×600 mm, in this case about 6000 vectors. For this task, a stereoscopic PIV system from the company TSI is used. It has a modular design, so that all symmetrical, asymmetrical and independent arrangements of cameras and light sheet can be realized. Thus, for example, it is possible to measure the full depth of the towing tank.

Please read more about the technical specifications of this PIV system here.

Context Related References / Research Projects

[1] Anschau, P.: Stereoskopische PIV-Messungen in Schlepprinne und Kavitationstunnel, Workshop Optische Strömungsmessverfahrenr, TU Dresden, 9. März 2011

[2] Anschau, P.: Stereoskopische PIV-Messungen an tiefgetauchten Schleppkörpern, TSI Seminar , Potsdam, 17. Oktober 2012

[3] Kleinwächter, A., Hellwig-Rieck, K., Ebert, E., Kostbade, R., Heinke, H.-J., Damschke, N. A.: PIV as a Novel Full-Scale Measurement Technique in cavitation Research, Fourth International symposium on Marine Propulsors, smp´15, Austin, Texas, USA, June 2015

Laser Doppler Anemometry

Please read more about our 3 components LDV system here.

ESD – Energy Saving Devices

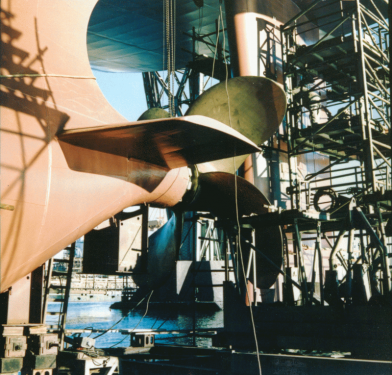

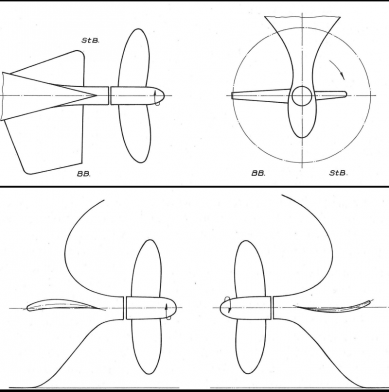

The development of ESDs has been worked on already since the 70s. The focus was on the influence of after-body forms and bulges, propulsion and vibration excitation, design and testing of contra-rotating and overlapping propellers, and developing inflow-improving nozzles [1], [2], [3].

Asymmetric after-bodies and guide fins were used in the context of propulsion optimisation of ships for generating a pre-swirl in the propeller inflow to reduce the rotational losses of the propeller. The research and development in this area led to the SVA guide fin systems. Model tests with different types of ships and full-scale measurements show a potential of 2 to 5 % power savings through the use of SVA guide fin systems [4], [5], [6]. Various R & D projects have been processed in order to improve the design of propellers and ESDs. Potential flow methods are used for the design and optimisation of propellers. Viscous calculation methods and experiments are used to verify the design, the prognosis of scale effects and applied to the design and optimisation of propulsion systems such as ducted propellers, thrusters and ESDs. To check the design of the propeller, speed measurements are performed on propeller boss cap fins and rudder. The SVA-developed HVV outlet cover (Hub Vortex Vane), leads to a reduction of the hub vortex and reduces the energy loss of the propeller in the hub area.Systematic CFD calculations are performed for analysis of the effectiveness of Costa Bulb on rudder and to derive design cues [7]. These works were continued in R & D project BossCEff – “Increasing the Effective Degree of Propulsion and Controlling Boss Vortex Cavitation Through Improved Consideration of the Interaction Between Propeller Wash and Boss Cover” [8], [9]. In cooperation with the project partners Technical University of Hamburg-Harburg, The Institute of Fluid Dynamics and Ship Theory (FDS), and the Mecklenburger Metallguss GmbH (MMG), special propeller flow caps were developed and studied for use in rudders with Costa Bulbs and propeller boss covers with fins.

The Mecklenburg Metallguss GmbH developed in the collaborative projects BossCEff a new energy-saving propeller cap, MMG ESCAP®.

The propeller caps improve propulsion characteristics of the vessel on existing propellers and on propeller redesign projects. The ESCAP®, among others, has also been successfully applied in newly designed propellers.

The following maximum power savings were achieved for ships with ESDs by investigations of SVA [11], [12]:

| – Twisted Rudder | up to 1,4 % |

| Costa-Bulb with Twisted Rudders | up to 3,7 % |

| Costa-Bulb with Conventional Rudders | up to 3,5 % |

| Boss Cap Fins | up to 3,2 % |

| Propeller Redesign | up to 14 % |

| Wake Equalising Duct | up to 4,8 % |

| Becker Mewis Duct® | up to 10 % |

| Bulbous Bow Retro-fit | up to 21 % |

Context Related References / Research Projects

[1] Schmidt, D.: Propulsionsuntersuchungen mit Einzelpropeller und Gegenlaufpropeller am Modell eines Containerschiffes, Schiffbauforschung 14 1/2/1975

[2] Schmidt, D.: Der Einfluss der Form des Heckwulstes auf die Schwingungserregung durch den Propeller für ein Containerschiff, Schiffbauforschung 21 1/1982

[3] Schmidt, D.: Die Reduzierung der propellererregten Schwingungen durch nachstrombeeinflussende Änderungen am Hinterschiff,

Schiffbauforschung 23 3/1984

[4] Mewis, F., Peters, H.-E.: Verbesserung der Propulsion durch ein neuartiges Flossensystem Intern. Rostocker Schiffstechnisches Symposium, Schiffbauforschung, Sonderheft, Bd. 1, 1987

[5] Peters, H.-E., Mewis, F.: Das Leitflossensystem der SVA am Containerschiff Typ Saturn, HANSA Nr. 17/18, 1990

[6] Schmidt, D.: Nachrüstung von Motorgüterschiffen ermöglicht Leistungseinsparung, Binnenschiffahrt – ZfB Nr. 9, Sept. 1995

[7] Lübke, L.: Numerical Simulation of the Viscous Flow around Costa Bulbs, NUTTS 2002, Nantes, August 2002

[8] Greitsch, L., Pfannenschmidt, R., Abdel-Maksoud, M., Druckenbrod, M., Heinke, H.-J.: BossCEff – Steigerung des Propulsionswirkungsgrades durch Reduktion von Nabenwirbelverlusten, Statustagung „Maritime Technologien“, BMWE, Rostock, 10.12.2014

[9] Heinke, H.-J., Lübke, L. O., Steinwand, M.: Numerical and experimental investigations for influencing the propulsion efficiency in the hub region of the propeller, STG-Sprechtag “Hydrodynamic Performance of ESDs”, Hamburg, 09.10.2014

[10] Pfannenschmidt, R.; Greitsch, L.: Das MMG Re-Design-Programm, Hanse Sail Business Forum, 07.08.2014

[11] Heinke, H.-J., Lübke, L. O.: Maßnahmen zur Energieeinsparung, Schiff & Hafen, Nr. 10, 2014

[12] Heinke, H.-J., Hellwig-Rieck, K.: Investigation of Scale Effects on Ships with a Wake Equalizing Duct or with Vortex Generator Fins, Second International Symposium on Marine Propulsors, smp’11, Hamburg, Germany, June 2011