September, 20th saw a high rank visit from the German Bundestag at SVA Potsdam in the course of the “ZUSE-TAG REGIONAL” event. Please read the full article (in German only) here.

Author: pa

Mini Cupper Race 2018

On May 17th the traditional Mini Cupper Race of the Lürssen Group took place again. After last year’s race was cancelled due to adverse weather conditions, this year 22 yachts met for the 11th contest of this cup.

After a short explanation of the sailing and racing rules for the less experienced steersmen the race started. Under best weather conditions with a force 3 wind 7 challenges could be accomplished, seeing Lürssen-Kröger’s yacht with steersman Dietrich Kirchner clearly standing out against the competitors. With its CEO Dr. Christian Masilge at the joy stick of the remote control SVA Potsdam gained the 2nd place in the overall ranking, and the 3rd place was taken by Oldenburger Yacht Interior GmbH & Co. KG with steersman Jan Schoepe.

The race is being organised by Lürssen Group since 2007, featuring models of the Mini Cupper class with an overall length of 1.3 m at a weight of 8 kg. Eligible participants to this invitational tournament are business partners, customers and suppliers of the Lürssen Group. All yacht models are identical in order to maintain fair competition conditions.

Research Vessel ATAIR Laid on Keel

The ship overall length is 75 m with a moulded breadth of 17 m at a design draught of 5 m. It must be emphasized that ATAIR will be the first seagoing LNG driven ship of the German Federal Administration. The propeller has to fulfill the Silent-R classification requirements of DNV GL and was developed by SVA Potsdam. Both cavitation tests and pressure pulse measurements showed that the propeller design will meet these requirements.

The new ATAIR will replace the 30 years old precursor ship and will be put into service in 2020.

Successful Approval of QM System

The services and the quality of our company have an impact on the successful business activities of our customers. Since 1995, SVA Potsdam GmbH has been following an ISO DIN EN 9001 certified quality management system.

Once again this year, DNV GL Business Assurance Zertifizierung & Umweltgutachter GmbH approved the successful application of our QM system to research, development and services in the area of hydrodynamics. The certificate can be viewed here.

Our company also operates as a DIN EN ISO/IEC 17025 certified test laboratory (DAkkS certificate No. D-PL-15182-01-00). The certification covers the measurement of moving and non-moving objects in steady and unsteady water flows, the measurement of forces, moments and rotational speeds of rotating objects in water and fixed objects subjected to a water flow. The expertise of the test laboratory for this kind of measurements were once again approved by Deutsche Akkreditierungsstelle (DAkkS) in November 2017.

Update ==> 112th Plenary Meeting of Schiffbautechnische Gesellschaft e. V.

This year, the 112th plenary meeting of the Schiffbautechnische Gesellschaft e.V. (STG, The German Society for Maritime Technology) took place from 22nd to 24th November 2017 in Potsdam, Germany. The meeting started with the time-honoured Georg Weinblum Commemoration Lecture at the Schiffbau-Versuchsanstalt Potsdam GmbH (SVA). The lecture on „Development of CFD Methods for Industrial Ship Flow Applications” was given by Prof. Takanori Hino (Yokohama National University).

In the course of the framework programme a guided tour through the SVA facilities could be taken, which attracted many of the participants. Selected areas of SVA were shown: model and propeller manufacturing, model outfitting, the Towing Tank, Cavitation Tunnel and the Friction Measurement Test Stand.

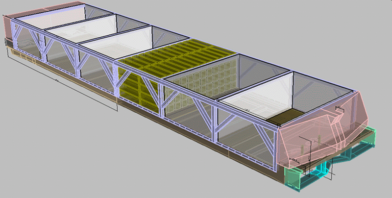

Outdoor Model Tests for the Evaluation of the Manoeuvrability of an „Inland Waterways Container Ship“

As part of an industrial project for the American Patriot Holdings LLC (APH) dealing with a new concept of an inland waterways container carrier (designed by NaviForm Consulting & Research), outdoor manoeuvring tests were conducted to complement the standard resistance and propulsion tests.

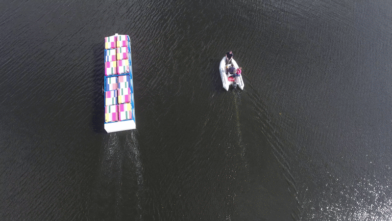

The manoeuvring tests were performed in a sheltered little bay of the Berlin part of the river Havel in the city of Spandau. The approximately 9 m long ship model (scale: 20) was manufactured at SVA Potsdam and, in accordance to NaviForm specifications, equipped with modelled superstructures and stylized containers. The ship was propelled by 4 VSPs, of which 2 were used solely for propulsion and the others mainly for manoeuvring purposes. The drives were provided by Voith Turbo GmbH & Co. KG. In the manoeuvring tests straight line, turning on the dime, turning circle and dock moving sidewise tests were conducted.

The tests were performed for a single draught. The thrust distribution scheme for the 4 drives which was identified as the best during previously conducted towing tank tests was also used in the outdoor tests. For full scale speeds of 8 kn and 12 kn straight line and turning circle manoeuvres were demonstrated.

The model tests were documented with video recordings. Beside a stationary camera a quadrocopter drone was used that provided recordings from different views of the manoeuvring behaviour of the ship.

The results showed that the targeted speed of 12 kn in straight line test could easily be achieved with the optimized thrust distribution scheme for the 4 VSPs. A turning circle with a diameter of less than 7 ship lengths can be achieved for a velocity of 8 kn and a thrust direction of 10°. At 12 kn the diameter of the turning circle spans about 7 ship lengths.

Due to the utilization of a purpose built wing system at the ship’s bow a considerably reduced wave system could be observed even at a speed of 12 kn.

In general a very good manoeuvring performance could be demonstrated for this inland waterways container carrier.

Author: Dr.-Ing. Matthias Fröhlich, Schiffbau-Versuchsanstalt Potsdam GmbH