Author: pl

Kavitationsbedingungen @en

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur lectus elit, porttitor quis placerat eget, porttitor eget nunc. Aliquam vel ex lectus. Sed ultricies sed nisi vitae faucibus. Integer sit amet dapibus dolor. Proin tincidunt orci a neque convallis tincidunt. Sed consectetur vel ex sit amet euismod. Praesent commodo ex id ligula porttitor semper. Morbi tempus justo id nisl mattis, eu laoreet sapien suscipit. Aenean est lacus, sodales nec varius vel, convallis sit amet nisl. Cras eleifend, ante vel tempus aliquam, tellus orci tristique nisl, nec convallis diam metus at diam. Proin egestas mauris ligula, in elementum ex efficitur eget. Praesent viverra commodo lacus, eget molestie dui molestie sed. Aliquam nec mollis quam. Phasellus euismod consectetur tincidunt. Phasellus sit amet felis elementum, bibendum dolor quis, blandit magna.

Curabitur eu massa vitae turpis laoreet molestie in eu velit. Nunc in condimentum nisl. Suspendisse potenti. Nullam ante ex, varius nec dignissim faucibus, suscipit vel eros. Aliquam condimentum nisi sit amet est vestibulum tincidunt. Quisque nisl enim, tempor in porttitor sed, ornare ac massa. Mauris sed convallis nisl. Aenean volutpat finibus turpis. Ut porta sagittis ligula congue vestibulum.

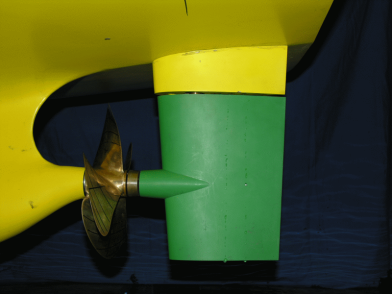

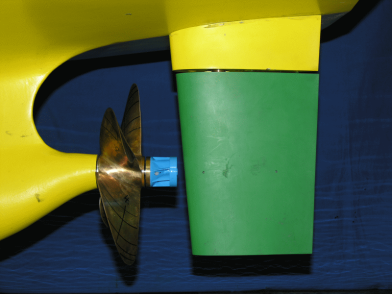

Paint Test

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur lectus elit, porttitor quis placerat eget, porttitor eget nunc. Aliquam vel ex lectus. Sed ultricies sed nisi vitae faucibus. Integer sit amet dapibus dolor. Proin tincidunt orci a neque convallis tincidunt. Sed consectetur vel ex sit amet euismod. Praesent commodo ex id ligula porttitor semper. Morbi tempus justo id nisl mattis, eu laoreet sapien suscipit. Aenean est lacus, sodales nec varius vel, convallis sit amet nisl. Cras eleifend, ante vel tempus aliquam, tellus orci tristique nisl, nec convallis diam metus at diam. Proin egestas mauris ligula, in elementum ex efficitur eget. Praesent viverra commodo lacus, eget molestie dui molestie sed. Aliquam nec mollis quam. Phasellus euismod consectetur tincidunt. Phasellus sit amet felis elementum, bibendum dolor quis, blandit magna.

Curabitur eu massa vitae turpis laoreet molestie in eu velit. Nunc in condimentum nisl. Suspendisse potenti. Nullam ante ex, varius nec dignissim faucibus, suscipit vel eros. Aliquam condimentum nisi sit amet est vestibulum tincidunt. Quisque nisl enim, tempor in porttitor sed, ornare ac massa. Mauris sed convallis nisl. Aenean volutpat finibus turpis. Ut porta sagittis ligula congue vestibulum.

Slow Steaming & Re-Design

Bulbous Bow retrofit

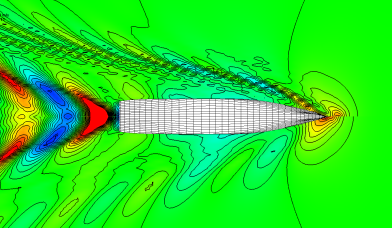

To minimize the cost of fuel, ships are now operated at lower speeds than a few years ago. Whereas with a 5-year-old container ship the Froude number is based on the design speed in a range from 0.21 to 0.25, these ships are now in a Froude number range of about 0.14 to 0.16. The speed reduction alone already results in significant fuel savings. In most cases, however, the bulbous bow is no longer optimal for the new, reduced speed range.

The original bulbous bow, which had been optimised for a Froude number of 0.21, but is running at a reduced Froude number of 0.145, produces an unfavourable wave system. The use of an optimised bulb for the new, reduced speed, in this case has led to a power saving of up to 8 %.

The SVA Potsdam uses the FRIENDSHIP-Framework for bulbous bow optimisations. Structured and unstructured grid topologies are generated for CFD calculations based on the parametrically described geometry. The numerical calculations are performed with the ANSYS CFX program. In a multi-point optimisation, the ship lines are optimised with the required power and uniformity of the wake field as a target function.

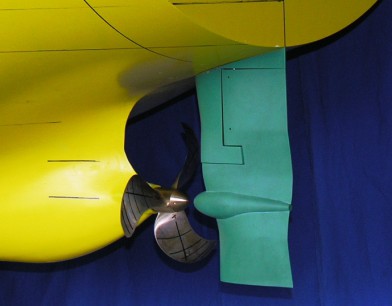

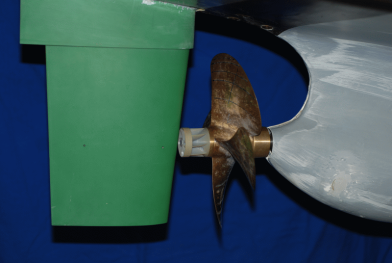

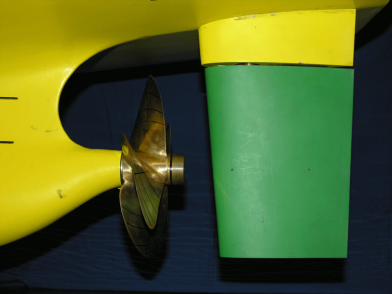

Propeller Re-Design

The lower thrust loading of the propeller in slow steaming results in greater freedom for propeller designs. Through increasing the propeller diameter, reducing the frequency of rotation, reducing the number of blades and the area ratio of the propeller, as well as the fine optimisation of the propeller blades, significant efficiency improvements can be achieved compared to the existing propeller, which was designed for higher vessel speeds. For large container ships, 6-bladed propellers are replaced with 5-bladed propellers with the transition to slow steaming. With a simultaneous increase of the propeller diameter by up to 5 % and reduction of area ratio by a third, power savings of 9 – 14 % can be demonstrated in experiments.

For the significantly slower bulk carriers, 4- and 3-bladed propellers are increasingly designed and investigated for both re-design projects as well as for the construction of new vessels. The area ratios of these propellers are in the range of AE/A0 = 0.35 to 0.45. Systematic investigations have shown that the 3-bladed propellers generate marginally higher pressure fluctuation amplitude in the first blade harmonics number. If the 3-bladed propeller is designed with a sufficient skew angle, the pressure fluctuation amplitudes of the higher blade number harmonics are in the range of propellers with a higher number of blades.

Context Related References / Research Projects

[1] Heinke, H.-J.; Lübke, L. O.: Maßnahmen zur Energieeinsparung, Schiff & Hafen, Nr. 10, 2014

Bulk Carrier

Ut a nisl id ante tempus hendrerit. Fusce risus nisl, viverra et, tempor et, pretium in, sapien. Nullam cursus lacinia erat. Fusce vel dui. Nullam vel sem.

Sed magna purus, fermentum eu, tincidunt eu, varius ut, felis. Etiam rhoncus. Suspendisse faucibus, nunc et pellentesque egestas, lacus ante convallis tellus, vitae iaculis lacus elit id tortor. Suspendisse faucibus, nunc et pellentesque egestas, lacus ante convallis tellus, vitae iaculis lacus elit id tortor. Donec venenatis vulputate lorem.

Praesent ac massa at ligula laoreet iaculis. Nam commodo suscipit quam. Praesent ac sem eget est egestas volutpat. Nam ipsum risus, rutrum vitae, vestibulum eu, molestie vel, lacus. Ut tincidunt tincidunt erat.

Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. Suspendisse pulvinar, augue ac venenatis condimentum, sem libero volutpat nibh, nec pellentesque velit pede quis nunc. Fusce a quam. Mauris sollicitudin fermentum libero. Pellentesque posuere.

Fusce ac felis sit amet ligula pharetra condimentum. Praesent ac massa at ligula laoreet iaculis. Nulla facilisi. Donec orci lectus, aliquam ut, faucibus non, euismod id, nulla. Maecenas vestibulum mollis diam.

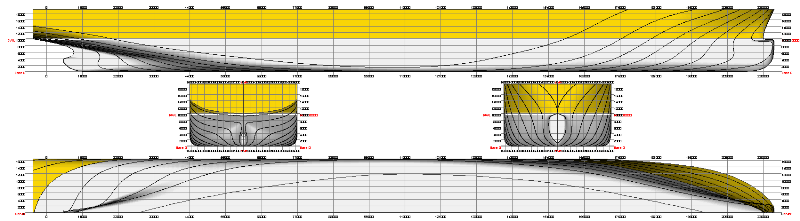

Ship Design

Good ship lines are the basis for the efficient and safe operation of a vessel. Clients of SVA are supported in the development of optimal ship lines by experienced engineers and the use of effective calculation tools. The design process takes place in close cooperation with the client and is accompanied by CFD calculations. With the results of the CFD calculations, a speed and performance prediction can be created. For lines development at the SVA Potsdam, the programs CAESES and DELFTship Professional are used. The CFD calculations are performed with the viscous CFD solvers ANSYS CFX and Fluent. In order to assess the seakeeping behaviour of a ship design, the SVA Potsdam uses the UTHLANDE program package.

If the main dimensions are not fixed, the SVA Potsdam provides parametric studies according to the prescribed specifications. By means of CFD calculations, statistical methods and the SVA database the best values for parameters such as main dimensions (L, B, T) or coefficient (CB, CM, LCB …) are hereby determined. From this, the impact of changes in various shape parameters can be determined on the performance of the vessel.

Context Related References / Research Projects

[1] Abdel-Maksoud, M.: Advantage of Application of CFD Methods in Ship Form Development, AEA – SVA Forum, Potsdam, 23rd March 2001

[2] Grabert, R., Rieck, K.: Hull Form Optimisation of Ferries Using CFD, 10. SVA-Forum, Potsdam, 26. Juni 2003

[3] Lübke, L.: STG 2009 – CFD-basierte Schiffsformoptimierung CFD-Sprechtag der STG, Hamburg, 25. September 2009

[4] Steinwand, M.: High Efficiency Design in der SVA, 5. SVA-Forschungsforum, Potsdam, 26. Januar 2012

[5] Lübke, L.: CFD in Ship design, ANSYS Conference & 32nd CADFEM Users` Meeting 2014