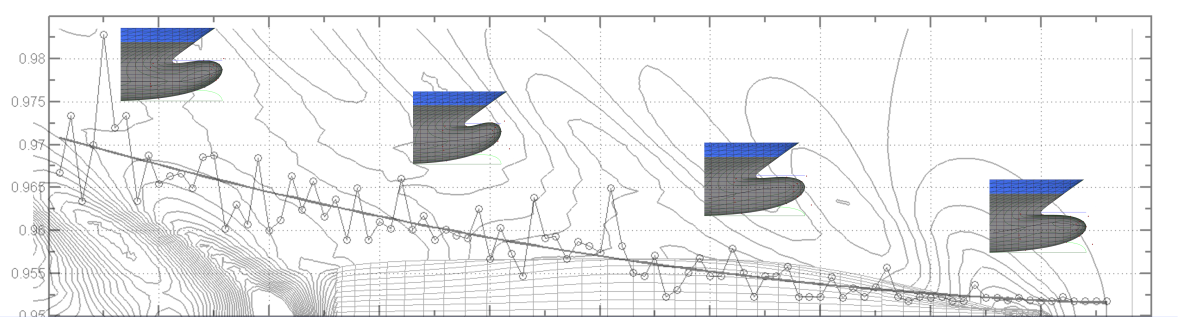

For this optimisation, among other things, various parametric models of the “CAESES” software are used. The optimisation is done on the basis of viscous CFD calculations, since these are considerably more reliable in optimising than the potential theory method. The savings benefits are generally considerable and give, over the life of the vessel, a significant increase of the “return on investment”. Classical optimisation tasks are the optimisation of bows, bulbous bows, and sterns. While on new designs an optimal concept is at once available, in the area of retrofitting, especially a bulbous bow, optimisation makes sense. Generally, this is done for the customer’s predefined mission profile fully parametrically. The example shows the development of the drag resistance of a ship geometry depending on the variation of the bulbous bow.

As a secondary condition of minimum resistance or propeller thrust, optimisation of the flow into a propeller (homogeneity of the wake) can be considered.

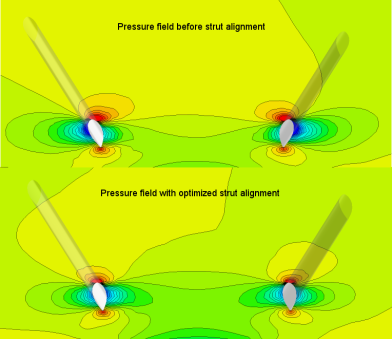

Propeller struts, stabiliser fins and other appendages can make a significant contribution to the ship’s resistance. Through the optimised shape and alignment of the appendages, the resistance and the loading of the attachments are minimised. Accordingly the propeller wash becomes homogeneous, improving the quality and efficiency of propulsion and contributing to the reduction of vibration and noise.

Context Related References / Research Projects

[1] Lübke, L.: Optimierung von Schiffsanhängen an großen Yachten, Fachseminar Numerische Simulation und Optimierung, Berlin, 24.05.2007

[2] Lübke, L.: Formoptimierung unter Berücksichtigung der Charakteristik des Nachstromfeldes, Forschungsthema, 04/2007 – 12/2009

[3] Lübke, L.: CFD in Ship Design, STG Sprechtag, 25.09.09 Hamburg

[4] Lübke, L.: CFD in Ship Design, ANSYS Conference & 32nd CADFEM Users Meeting 2014, Nürnberg, June 4-6, 2014