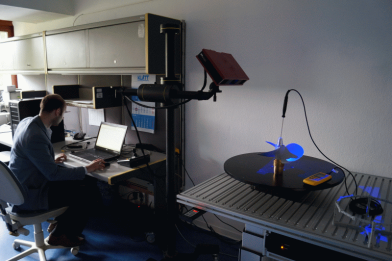

The SVA owns a 3D scanner system (ATOS Core 300) with the following parameters:

- Accuracy of 18 µm

- Object size with high accuracy (18 µm): 300 x 230 x 300 mm³

- Object size at a lower accuracy (50 µm): 600 x 600 x 600 mm³

- Manual two axes adjustment (lifting table, rotary table)

- Projection of 3D elements

- Automatic report creation

The ATOS Core 300 is used in production and quality control as follows:

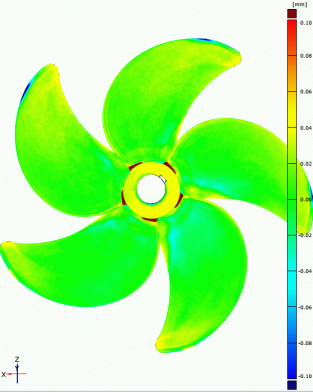

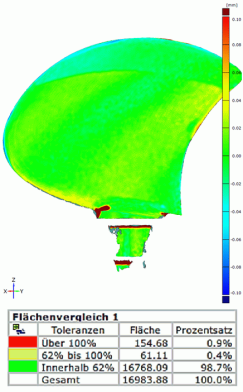

- Scanning of the geometry after milling (while model is still in the milling block). When the predetermined allowance is not reached locally, the milling process is continued.

- Scanning of the model after the removal from the milling block and the evaluation of the target – actual comparison with colleagues of the workshop in order to specify the steps in the manual finishing.

- Scanning of the model after completion, analysis of target – actual comparison, preparation of proof of compliance with the quality criteria and creation of an examination report.

Furthermore, components, test objects and geometries from existing measurement systems are recorded with the 3D scanner and provided for use in new experimental arrangements.